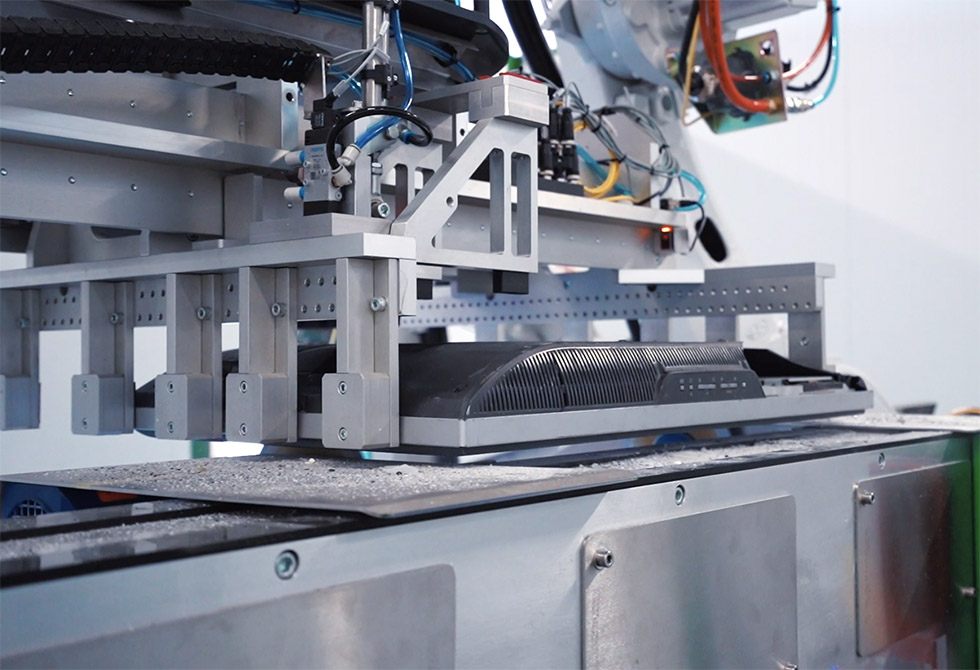

The FPD Pro dismantling robot at work in file photo from 2019. | Courtesy of FPD Recycling[/caption]

Pennsylvania-based eLoop will become the first U.S. e-scrap company to install a robotic flat-panel display dismantling system from FPD Recycling.

The company is installing at its State College, Pa. facility the FPD PRO, which uses artificial intelligence and robotics to automatically disassemble TVs, monitors and laptop screens, securing hazardous components such as mercury-bearing lamps.

The system is the product of years of R&D from Irish tech company FPD Recycling.

The installation of the automated system comes as the weight of CRT display devices in the end-of-life stream declines, giving way to increasing volumes of flat-panel TVs. For example, California program statistics show that non-CRT display devices made up 53% of the weight recycled through the state program last year, with the rest being CRTs. In the first quarter of 2022, non-CRT display devices made up about 62% of the weight.

Flat panels are fairly labor intensive to dismantle, and their net commodity values are limited. They're also made of components with toxic metals, such as mercury, cadmium and lead, that can be released if shredded or broken during manual disassembly.

"Because of the hazardous elements involved and the extensive manual labor required, the current method of disassembling FPDs for recycling purposes is inefficient, costly and potentially harmful to the worker," Ned Eldridge, eLoop’s CEO and founder, stated in a press release. “Improved productivity with the FPD PRO will allow us to provide this low-cost solution to recyclers so that they no longer have to expose their workers to hazardous elements in manually disassembling flat screens.”

Eldridge estimated a worker can disassemble about four flat screens an hour, and FPD Pro can break down about 90 an hour.

"This is a game changing breakthrough," he said.

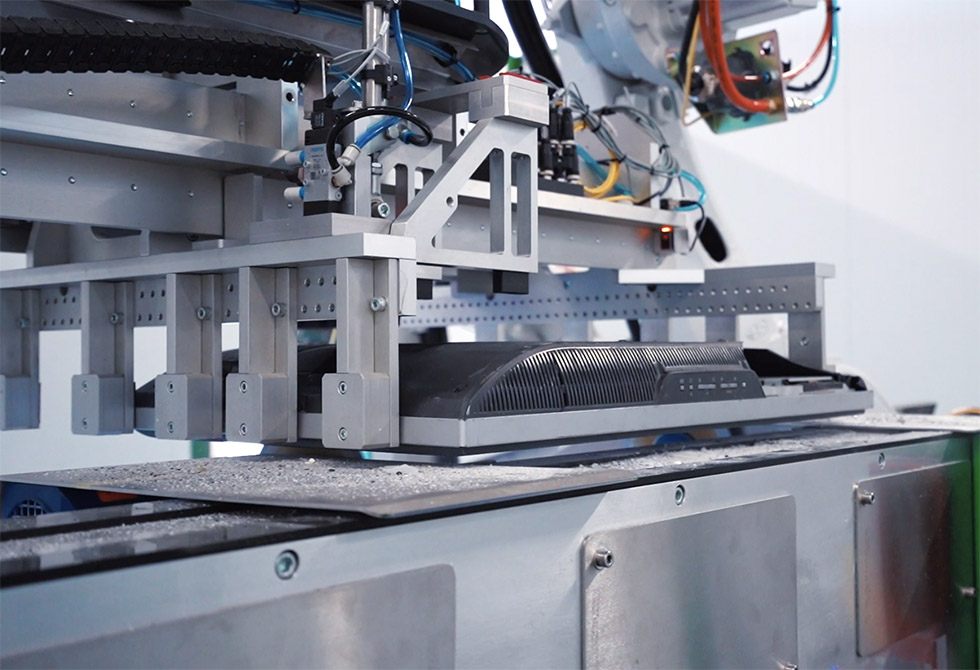

The FPD Pro dismantling robot at work in file photo from 2019. | Courtesy of FPD Recycling[/caption]

Pennsylvania-based eLoop will become the first U.S. e-scrap company to install a robotic flat-panel display dismantling system from FPD Recycling.

The company is installing at its State College, Pa. facility the FPD PRO, which uses artificial intelligence and robotics to automatically disassemble TVs, monitors and laptop screens, securing hazardous components such as mercury-bearing lamps.

The system is the product of years of R&D from Irish tech company FPD Recycling.

The installation of the automated system comes as the weight of CRT display devices in the end-of-life stream declines, giving way to increasing volumes of flat-panel TVs. For example, California program statistics show that non-CRT display devices made up 53% of the weight recycled through the state program last year, with the rest being CRTs. In the first quarter of 2022, non-CRT display devices made up about 62% of the weight.

Flat panels are fairly labor intensive to dismantle, and their net commodity values are limited. They're also made of components with toxic metals, such as mercury, cadmium and lead, that can be released if shredded or broken during manual disassembly.

"Because of the hazardous elements involved and the extensive manual labor required, the current method of disassembling FPDs for recycling purposes is inefficient, costly and potentially harmful to the worker," Ned Eldridge, eLoop’s CEO and founder, stated in a press release. “Improved productivity with the FPD PRO will allow us to provide this low-cost solution to recyclers so that they no longer have to expose their workers to hazardous elements in manually disassembling flat screens.”

Eldridge estimated a worker can disassemble about four flat screens an hour, and FPD Pro can break down about 90 an hour.

"This is a game changing breakthrough," he said.

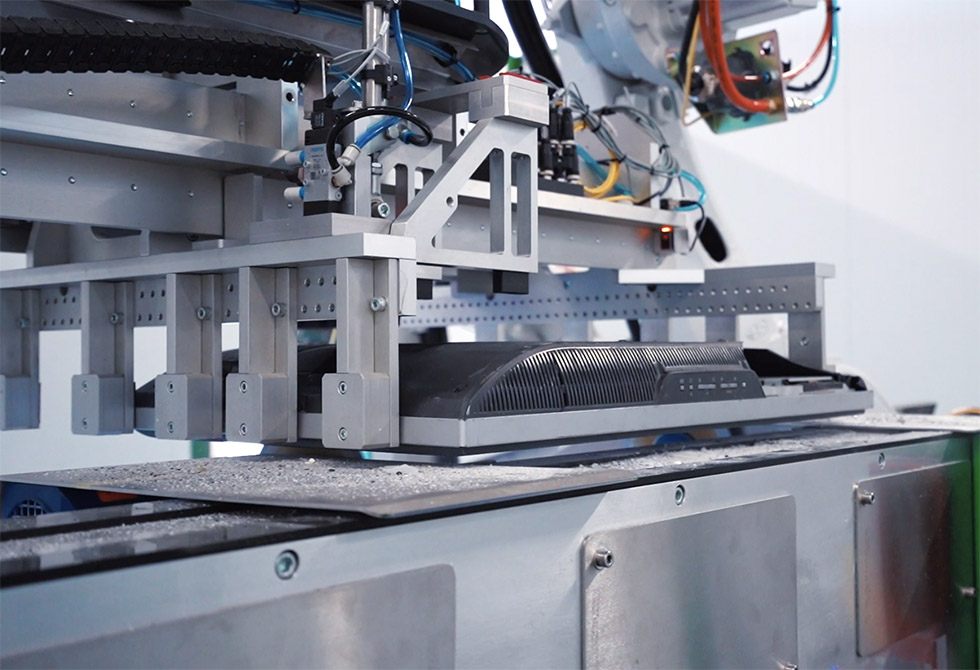

[caption id="attachment_12383" align="aligncenter" width="980"] The FPD Pro dismantling robot at work in file photo from 2019. | Courtesy of FPD Recycling[/caption]

Pennsylvania-based eLoop will become the first U.S. e-scrap company to install a robotic flat-panel display dismantling system from FPD Recycling.

The company is installing at its State College, Pa. facility the FPD PRO, which uses artificial intelligence and robotics to automatically disassemble TVs, monitors and laptop screens, securing hazardous components such as mercury-bearing lamps.

The system is the product of years of R&D from Irish tech company FPD Recycling.

The installation of the automated system comes as the weight of CRT display devices in the end-of-life stream declines, giving way to increasing volumes of flat-panel TVs. For example, California program statistics show that non-CRT display devices made up 53% of the weight recycled through the state program last year, with the rest being CRTs. In the first quarter of 2022, non-CRT display devices made up about 62% of the weight.

Flat panels are fairly labor intensive to dismantle, and their net commodity values are limited. They're also made of components with toxic metals, such as mercury, cadmium and lead, that can be released if shredded or broken during manual disassembly.

"Because of the hazardous elements involved and the extensive manual labor required, the current method of disassembling FPDs for recycling purposes is inefficient, costly and potentially harmful to the worker," Ned Eldridge, eLoop’s CEO and founder, stated in a press release. “Improved productivity with the FPD PRO will allow us to provide this low-cost solution to recyclers so that they no longer have to expose their workers to hazardous elements in manually disassembling flat screens.”

Eldridge estimated a worker can disassemble about four flat screens an hour, and FPD Pro can break down about 90 an hour.

"This is a game changing breakthrough," he said.

The FPD Pro dismantling robot at work in file photo from 2019. | Courtesy of FPD Recycling[/caption]

Pennsylvania-based eLoop will become the first U.S. e-scrap company to install a robotic flat-panel display dismantling system from FPD Recycling.

The company is installing at its State College, Pa. facility the FPD PRO, which uses artificial intelligence and robotics to automatically disassemble TVs, monitors and laptop screens, securing hazardous components such as mercury-bearing lamps.

The system is the product of years of R&D from Irish tech company FPD Recycling.

The installation of the automated system comes as the weight of CRT display devices in the end-of-life stream declines, giving way to increasing volumes of flat-panel TVs. For example, California program statistics show that non-CRT display devices made up 53% of the weight recycled through the state program last year, with the rest being CRTs. In the first quarter of 2022, non-CRT display devices made up about 62% of the weight.

Flat panels are fairly labor intensive to dismantle, and their net commodity values are limited. They're also made of components with toxic metals, such as mercury, cadmium and lead, that can be released if shredded or broken during manual disassembly.

"Because of the hazardous elements involved and the extensive manual labor required, the current method of disassembling FPDs for recycling purposes is inefficient, costly and potentially harmful to the worker," Ned Eldridge, eLoop’s CEO and founder, stated in a press release. “Improved productivity with the FPD PRO will allow us to provide this low-cost solution to recyclers so that they no longer have to expose their workers to hazardous elements in manually disassembling flat screens.”

Eldridge estimated a worker can disassemble about four flat screens an hour, and FPD Pro can break down about 90 an hour.

"This is a game changing breakthrough," he said.

The FPD Pro dismantling robot at work in file photo from 2019. | Courtesy of FPD Recycling[/caption]

Pennsylvania-based eLoop will become the first U.S. e-scrap company to install a robotic flat-panel display dismantling system from FPD Recycling.

The company is installing at its State College, Pa. facility the FPD PRO, which uses artificial intelligence and robotics to automatically disassemble TVs, monitors and laptop screens, securing hazardous components such as mercury-bearing lamps.

The system is the product of years of R&D from Irish tech company FPD Recycling.

The installation of the automated system comes as the weight of CRT display devices in the end-of-life stream declines, giving way to increasing volumes of flat-panel TVs. For example, California program statistics show that non-CRT display devices made up 53% of the weight recycled through the state program last year, with the rest being CRTs. In the first quarter of 2022, non-CRT display devices made up about 62% of the weight.

Flat panels are fairly labor intensive to dismantle, and their net commodity values are limited. They're also made of components with toxic metals, such as mercury, cadmium and lead, that can be released if shredded or broken during manual disassembly.

"Because of the hazardous elements involved and the extensive manual labor required, the current method of disassembling FPDs for recycling purposes is inefficient, costly and potentially harmful to the worker," Ned Eldridge, eLoop’s CEO and founder, stated in a press release. “Improved productivity with the FPD PRO will allow us to provide this low-cost solution to recyclers so that they no longer have to expose their workers to hazardous elements in manually disassembling flat screens.”

Eldridge estimated a worker can disassemble about four flat screens an hour, and FPD Pro can break down about 90 an hour.

"This is a game changing breakthrough," he said.

The FPD Pro dismantling robot at work in file photo from 2019. | Courtesy of FPD Recycling[/caption]

Pennsylvania-based eLoop will become the first U.S. e-scrap company to install a robotic flat-panel display dismantling system from FPD Recycling.

The company is installing at its State College, Pa. facility the FPD PRO, which uses artificial intelligence and robotics to automatically disassemble TVs, monitors and laptop screens, securing hazardous components such as mercury-bearing lamps.

The system is the product of years of R&D from Irish tech company FPD Recycling.

The installation of the automated system comes as the weight of CRT display devices in the end-of-life stream declines, giving way to increasing volumes of flat-panel TVs. For example, California program statistics show that non-CRT display devices made up 53% of the weight recycled through the state program last year, with the rest being CRTs. In the first quarter of 2022, non-CRT display devices made up about 62% of the weight.

Flat panels are fairly labor intensive to dismantle, and their net commodity values are limited. They're also made of components with toxic metals, such as mercury, cadmium and lead, that can be released if shredded or broken during manual disassembly.

"Because of the hazardous elements involved and the extensive manual labor required, the current method of disassembling FPDs for recycling purposes is inefficient, costly and potentially harmful to the worker," Ned Eldridge, eLoop’s CEO and founder, stated in a press release. “Improved productivity with the FPD PRO will allow us to provide this low-cost solution to recyclers so that they no longer have to expose their workers to hazardous elements in manually disassembling flat screens.”

Eldridge estimated a worker can disassemble about four flat screens an hour, and FPD Pro can break down about 90 an hour.

"This is a game changing breakthrough," he said.

Categories